From the inventor of the sekurant

Anchor points

Anchor points are used as an attachment point for personal protective equipment against falls in an individual fall protection system. Anchor points are usually permanently connected to the structure and are equipped with an anchor eye or anchor strap to attach personal protective equipment against falls.

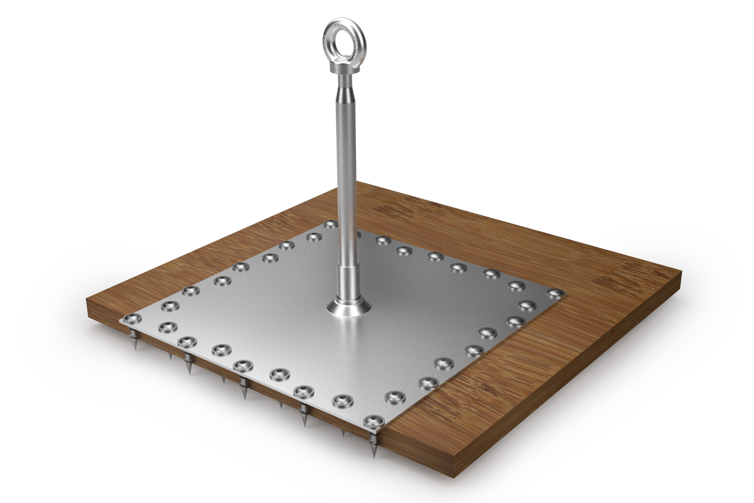

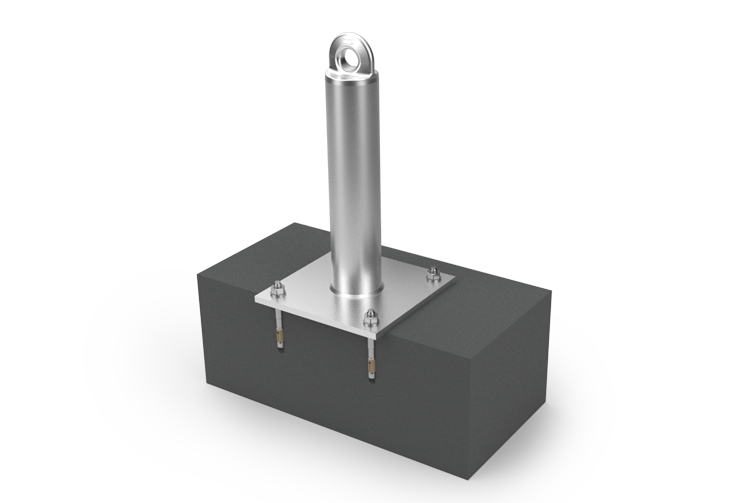

SECURANT POINT

SECURANT

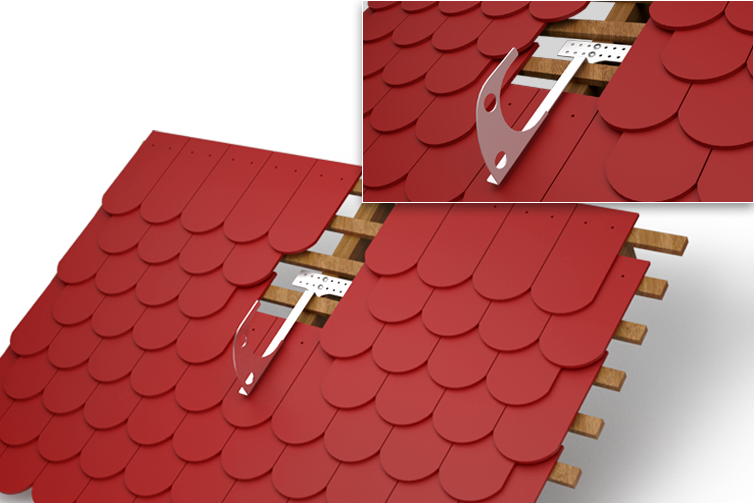

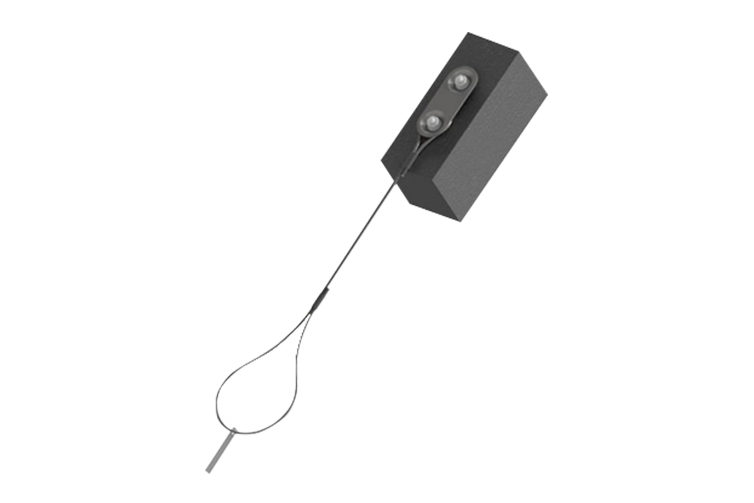

SECU hook

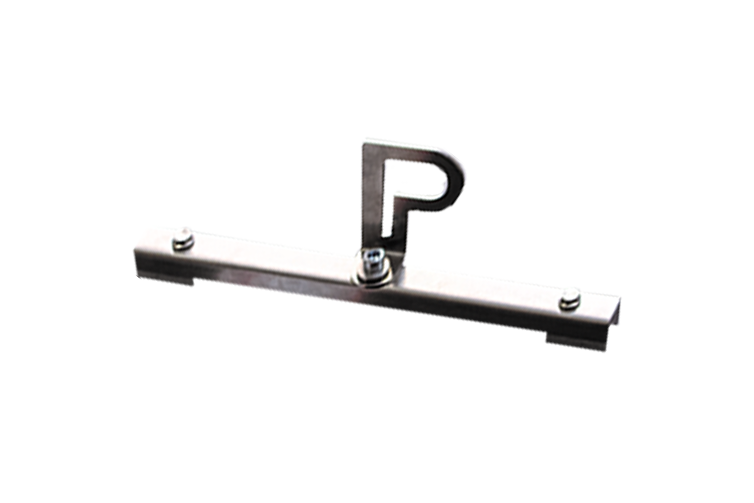

SECU Falz

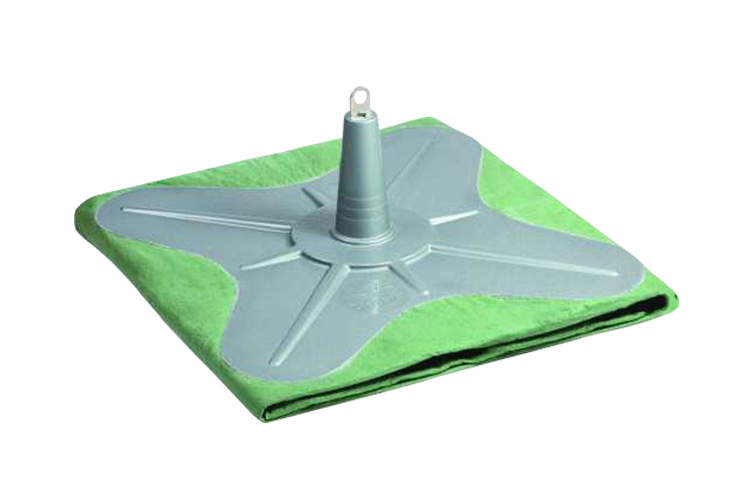

SECU Green

What is an anchor point?

An anchor point serves as a holder for various fall protection systems. An anchorage point is firmly attached to a surface on a roof or work surface at a height. Various lifeline systems can then be attached to it, which are used to secure individual persons from falling.

An anchor point, like the lifeline systems, is one of the so-called secondary fall protection systems. Because these ensure that people are individually secured when working at great heights.

Why do you need anchor points?

There are various professional groups who use an anchor point for securing when working at heights. This type of fall protection is particularly popular on flat roofs. But roofers, firefighters and industrial climbers also use the anchorage points to secure their work at a height. But these special securing points are also used for many other types of work at height.

Fall protection with an anchor point can prevent or intercept falls. Which type of belay system is used with this system depends on the combined lifeline system.

What is the difference between an anchor point and an anchor swivel?

There is a big difference between lifting points and lifting swivels. These should not be confused. While a swivel anchor is designed to lift large loads, this function is not important for an anchor point and therefore does not matter. The anchor point is only intended to ensure that the lifeline system is firmly anchored and offers sufficient safety to catch a fall.

What are the different variants of attachment points?

In general, two variants can be distinguished for the use of attachment points.

- Restraint system

With this variant, the anchorage point is used to use a corresponding lifeline system that ensures preventive avoidance of a fall. This prevents the worker from getting close to a falling edge. The anchor point is connected to the lifeline system, which then ensures the restricted radius and can thus prevent a fall.

- Fall arrest system

In this variant, the anchor point is used to provide the necessary safety in the event of a fall and to intercept the worker using the lifeline system. The anchor point serves as a bracket for the lifeline system and ensures that the load can be held. This, in combination with the appropriate lifeline system, can intercept the fall.

Regardless of the system, the anchor point always serves as a connection between the individual safety system and the solid base and thus represents the force that holds the worker in an emergency.

How is an anchor point used?

The anchor point is usually equipped with a corresponding eyelet. These eyelets are usually made of stainless steel and make it possible to connect the personal safety system to the anchorage point. The personal safety system usually consists of a special rope system that is then connected to the anchorage point. This holds the load in the event of a fall and, like climbing, provides the connection and support.

What kind of fall protection is an anchor point required for?

Attachment points are required for almost all personal security systems. Because the personal safety systems usually consist of rope systems that have to be connected to a fixed point in height. The fixed point is secured with an anchor point. In general, it can be said that attachment points, which are also referred to as anchors, are required for all secondary fall protection.

What are the different anchor point models?

The type of attachment point differs depending on the application and also on the substrate in which the attachment point is to be introduced. Factors such as the load-bearing capacity and the load placed on the material also play a role.

Appropriate attachment points must be used for the various substrates. There are different models for substrates such as:

- Lightweight concrete

- concrete

- Pumice

- Aerated concrete

- prestressed concrete

- wood

- stole

- Sandwich panels

But the location at which an attachment point is to be attached also plays an important role when choosing the model. There are other models for mounting on flat surfaces than for mounting on walls or ceilings. There are also various models that can be used as mobile anchor points.

In addition, the various models can also be differentiated according to the security system used. Because different models of attachment points are also suitable for the various securing systems. Depending on which surface, which position and which type of safety system should be used, the different attachment points are differently suitable. Before choosing a model, it is good to get advice from experts on site about the possibilities of fall protection.

What conditions must an anchor point meet?

In order to guarantee the highest level of safety, fall protection devices are required at different heights. It is not only important to find the right choice of the right system, but also the quality of the systems and the materials used.

Anchor points that may be used must therefore meet various guidelines in order to be approved for use. The material must be stable, robust and resilient and be subject to a high class of goods. For this reason, the attachment points are tested in accordance with the DIN standard DIN EN 795. The lifting points are only approved if this test is passed.

In addition, permanently installed attachment points must have a building inspectorate approval; the attachment points may only be permanently installed if this is available.

Strict adherence to these certifications is important because an anchor point is a secure anchor for working at height. If there are weaknesses in the material or workmanship, this can in the worst case cost life. Because in the event of a fall, particularly strong forces act on the anchorage point, which it has to withstand.

But it is not only the quality of the material and the anchorage point itself that represents safety, but above all the installation of the anchorage points must be carried out professionally. Because only if the attachment points are properly and professionally installed, the task of securing can also be guaranteed. It is therefore important that the people who are responsible for the installation are specially trained for this task, because this is the only way to ensure correct installation and thus the necessary safety. Attention must be paid to the highest quality and professional assembly.